GFRC (Glass Fiber Reinforced Concrete) Projects by Willis Construction

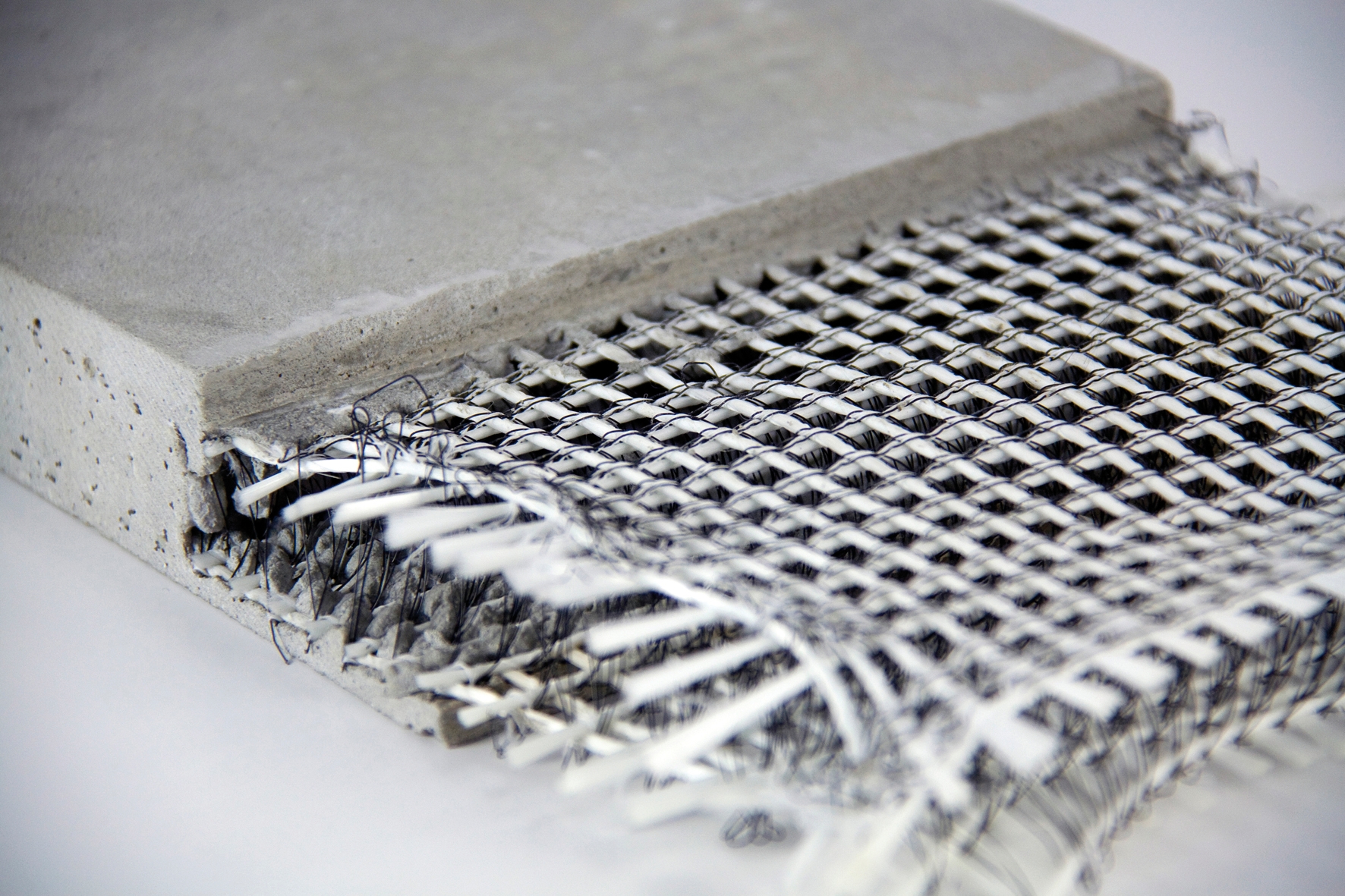

Glass fibre reinforced concrete ( GFRC) is a type of fibre-reinforced concrete. The product is also known as glassfibre reinforced concrete or GRC in British English. [1] Glass fibre concretes are mainly used in exterior building façade panels and as architectural precast concrete.

Glass Reinforced Concrete Synaxis Readmix Concrete

One such product is Glass Fiber Reinforced Concrete (GFRC). It is a composite, consisting of portland cement, fine aggregate, water, acrylic polymer, alkali-resistant glass fiber reinforcement and additives. GFRC is a lightweight, durable material that can be cast into nearly unlimited shapes, colors and textures It is mainly used in exterior.

Prosta Tower, Warsaw, Poland Projects PERI Tower, Skyscraper

In glass fiber reinforced concrete, the mode of failure was changed from brittle to ductile when polyvinylalcohol powder was added. 268 Polymer covered the fiber surface and protected it from accumulation and effect of calcium hydroxide as determined by electron microscopy and energy dispersive X-ray analysis. 268

Glass Fibre Reinforced Concrete Cladding PMJ Masonry

Glass fiber reinforced concrete (GFRC) comprises hydration products of cement, or cement plus sand, and the glass fibers. Glass fibers are used are used as reinforcement for concrete. Glass fibers were first used to reinforce cement and concrete in Russia. However they were corroded by the highly alkaline Portland cement matrix.

Glass Reinforced Concrete Aliva UK

Glassfibre Reinforced Concrete (GRC) is a cement-based composite material reinforced with alkali-resistant fibres. GRC can be formed into thin sectioned lightweight elements and provides designers, architects and engineers with substantial advantages when compared to other traditional concrete materials.

The Glass Fiber Reinforced Concrete Method Pool & Spa News

First, Formwork Buddy Rhodes Concrete Products Formwork for GFRC should be nonporous, with watertight seams. Melamine coated particle board or laminate is a common choice for large, flat.

Glass Fibre Reinforced Concrete Cladding PMJ Masonry

Prior studies in the literature show promising results regarding the improvements in strength and durability of concrete upon incorporation of glass fibers into concrete formulations. However, the knowledge regarding glass fiber usage in concrete is scattered. Moreover, this makes it challenging to understand the behavior of glass fiber-reinforced concrete. Therefore, a detailed review is.

Fiber Reinforced Concrete Explained A.L. Blair

Glass fibre reinforced concrete (GFRC) is a type of reinforced concrete made of glass fibres. It is a construction material made of cement and alkali-resistant glass fibres. The fibres replace steel reinforcing bars in reinforced concrete and provide greater flexural, tensile, and impact strength.

Glass Fiber Reinforced Concrete Chopped Stand China Fiberglass and

This paper provides a compressive analysis of glass fiber-reinforced composites. All-important properties of concrete such as flowability, compressive, flexural, tensile strength and modulus of elasticity were presented in this review article.

Luigi Rosselli Architects textured glass reinforced concrete (GRC

Glass-Fiber Reinforced Concrete (GFRC) is a composite material that blends traditional concrete components (cement, water, aggregates, and admixtures) with specially engineered glass fibers to create a final product with increased compressive, flexural, and tensile strength.

National Precast Concrete Association Australia Glass Reinforced

AR-glass fibers are also available as roving, which is a spool of a continuous length of multiple strands of glass fiber twisted together (typically 28 strands in a roving with 200 filaments per strand). In regular spray-up GFRC, this roving is fed into a chopper gun which cuts the fibers to a specific length as they are mixed with the concrete.

Image result for TEXTURED GFRC PANEL Concrete cladding, Concrete

Glass fiber reinforced concrete (GFRC) is well known for its high compressive strength-to-weight ratio. This benefit results from the high cement mixture and low water content. Other benefits are its high flexural strength (bending strength) and high tensile strength. GFRC also has appreciable load-bearing qualities.

GFRC (Glass Fiber Reinforced Concrete) Panels Mesa Precast

GFRC is a composite of cement, glass fibers, aggregates and polymers. Stromberg GFRC pioneered the design and production of glass fiber reinforced concrete and our unique methods of detailing, manufacturing and installing GFRC that have helped make our clients, and their projects, successful. With our 30 years experience, 1400+ completed.

Glass Fiber Reinforced Concrete (GFRC) Properties and Applications

Glass Fiber Reinforced Concrete is a mixture of cement, sand, polymer, and alkali-resistant glass fibers. This unique mixture obtains its strength from chopped fiberglass strands that allow products to be manufactured with thin walls without needing reinforcing bars.

The Glass Fiber Reinforced Concrete Method Pool & Spa News

Glass Fiber Reinforced Concrete (GFRC), also known as Glassfibre Reinforced Concrete (GRC), is a versatile engineered material composed of cement, aggregate, polymer, and fibers. This amalgamation creates a remarkably lightweight yet incredibly robust substance.

Tiles. Our own seannnnnnn makes beautiful things of GFRC (glass fiber

Glass Fiber Reinforced Concrete Mixes and Materials for GFRC Glass Fibers for GFRC Benefits of GFRC MANUFACTURING GFRC PIECES Rock panels are created using spray-up GFRC. Eldorado Wall Co. Larger architectural elements are created by directly spraying the premixed GFRC into a mold. NEGAmerica